PRODUCTION

Despite the greyness of everyday life, we live in color.

Search

Do you have toner or ink for my printer?

Production process controls according to ISO 9001, ISO 14001, and ISO 19752 and ISO 19798 standards, set in 2010, guarantee the same print quality and quantity as with genuine toner cartridges.

We don't compromise on chips either. They provide the user with impeccable comfort without sacrificing functionality! All components must work perfectly aligned and must provide at least as good quality and performance as the original product . Continuous quality control guarantees that the finished Print-team product is fully operational and much cheaper than OEM toner.

Microteam is confident in the quality of its products and therefore provides a 2 year warranty on all its products.

About production

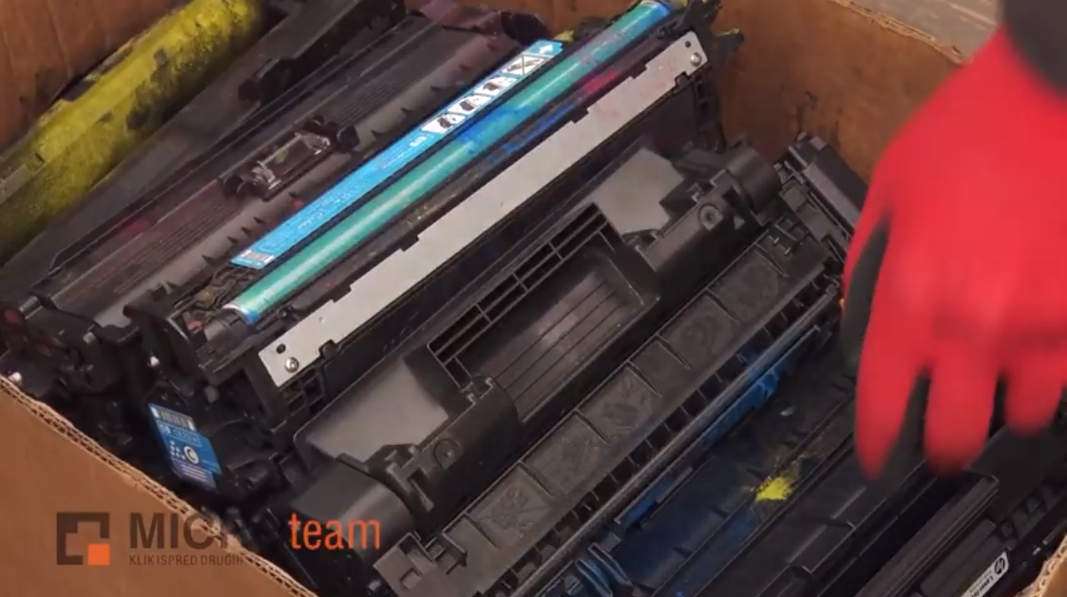

Recycled cassettes are recycled and remanufactured from original manufacturer's (OEM) empty cassettes.

This process differs according to the manufacturer and the materials used and varies in quality of results and coverage per print page. Print-team cartridges are manufactured to rigorous quality control standards (ISO 19752 and ISO 19798), using laboratory-tested components, to ensure the same quality and properties as with original toners.

HOW THE PRODUCTION PROCESS REALLY LOOKS?

The typical process consists of inspecting and replacing major components such as the OPC (Organic Photo Conductor) drum, wiper blade, PCR (Primary Charge Roller) and magnetic rollers. One of the most critical parts of the cassette is the OPC drum. New replacements are specifically made for manufacturers of renewable cassettes to have a harder, more durable surface than OEM cassettes. Only new drums are used in cartridge refurbishment to ensure the same results as with OEM products.

THE BEST TERMS YOU NEED TO KNOW IN PRINT-TEAM STORIES:

1. Separation and cleaning

Empty cassettes are carefully disassembled and cleaned with compressed air and a cotton cloth. The most common toner cleaners are water, alcohol, or gasoline

2. Fill the toner cartridge cartridge

caste cartridge fills with the correct toner for that type of cartridge that technically matches the OPC (drum) for optimum printer coverage and performance. The exact amount of powder for a particular cassette type is determined premisO 19752/19798

3. Sealing

Each toner cartridge is sealed with the seal as with the OEM manufacturer. The quality sealing process ensures easy installation by users without the possibility of leaking content

4. Assembling

Factory trained technicians assemble all cassettes with the mandatory replacement of the OPC drum. The assembly process involves the installation of a drum, wiper, PCR and magnetic roller and other parts

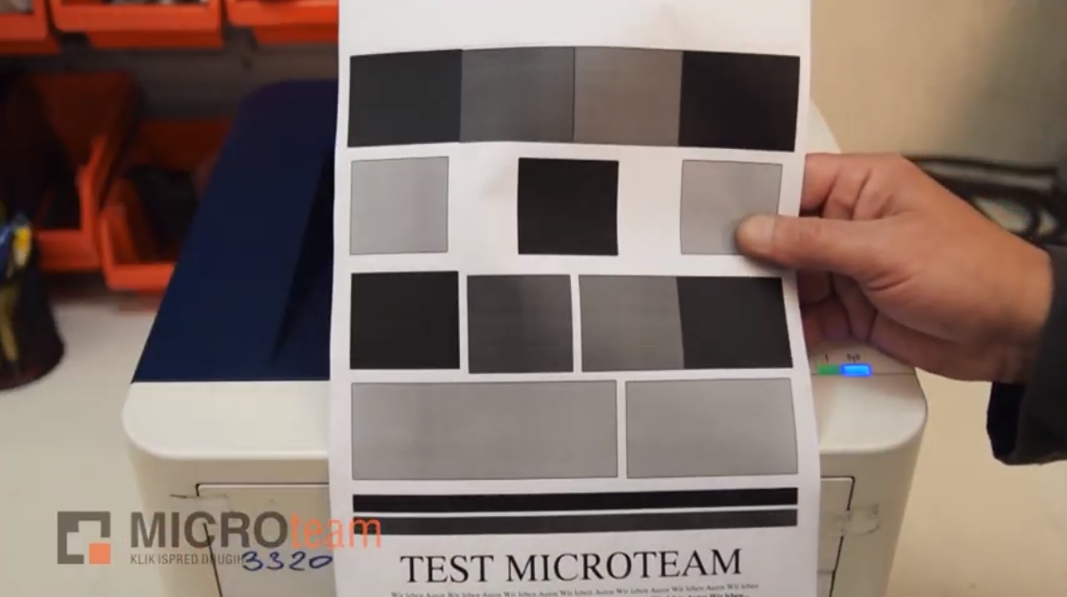

5. Post-Assembly Testing

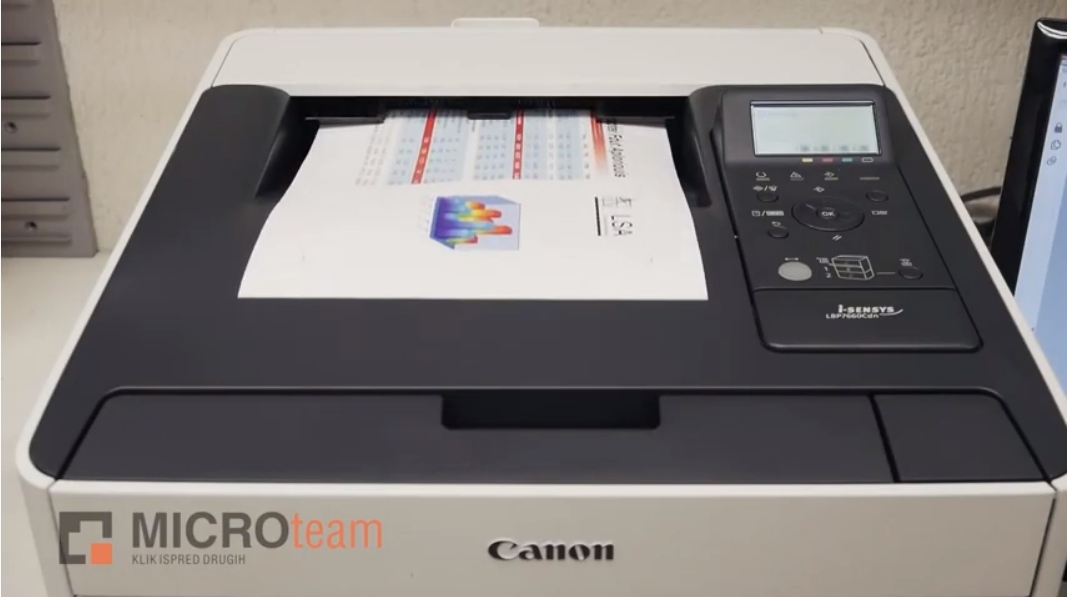

After assembly, each toner cartridge is tested against standardized manufacturer tests to achieve superior print results and quality. (several test sheets are printed to check the quality of color or gray scale prints for toners that print only in black)

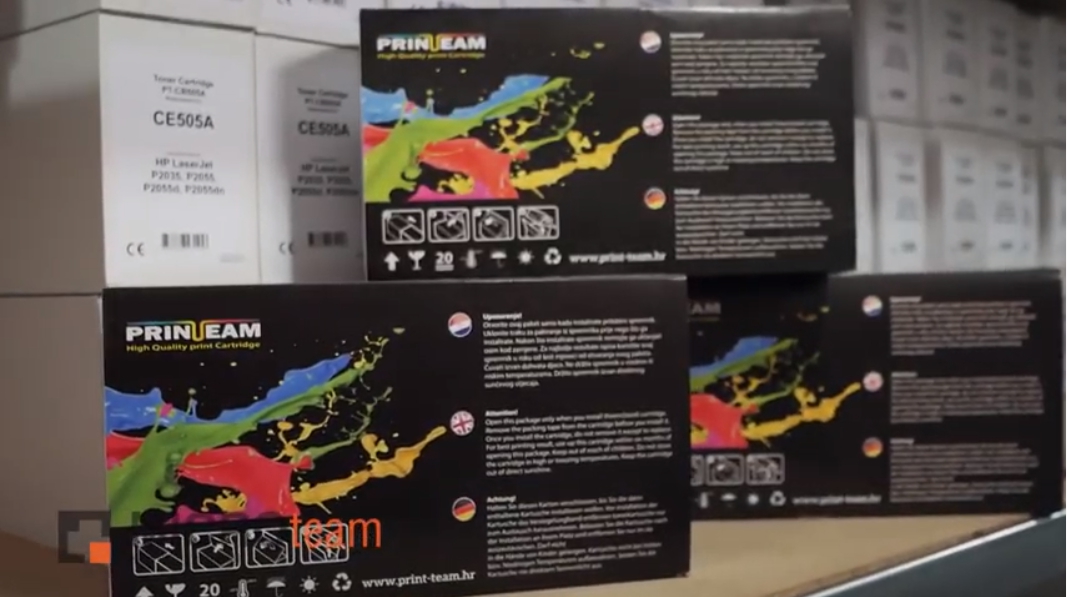

6. Packaging

All toner cartridges are subject to final inspection to ensure they meet strict quality standards. The cassettes are clean, polished, sealed in static-resistant bags and cases. The box contains a complete set of instructions and warranty information.

TONER CARTRIDGE PARTS

1. Cassette Tank

The main powder container made of plastic. Tank built into main body. Used for toner storage.

2. Seal

Removable protective tape to prevent toner from escaping before installation is used by HP and other manufacturers.

3. Doctor blade

Provides continuous accurate toner distribution to the development unit or magnetic roller.

4. Development Unit or Magnetic Roller

Transfers toner to the OPC drum. Also called a magnetic roller in systems that use a magnet to attract toner (containing magnetite) for transfer to the drum.

5. Wiper blade

Keeps in contact with the drum and clears the drum from all toner residue after applying it to the page.

6. Waste Tank

Collects the remains of toner wiped from the OPC drum because it has been through the process.

7. Pcr roller

Edits or charges the OPC drum before laser imaging. This is achieved by applying a single negative charge. PCR also empties or deletes the laser image.

8. Organic photo condutor - opc roller - opc drum

Aluminum drum coated with a multilayer film film, precisely shaped with extremely low tolerances to ensure an optimally curved surface. Since the surface quality of the OPC drum is the surest way to ensure the quality of the cassette, only new OPC drums are used in refurbishing the cassettes.

9. Drum Lock

Protects the OPC drum from exposure to light while the cassette is out of the printer and into the printer.

HOW DOES TONER WORK?

The toner is transferred from the main cartridge to the magnetic roller (the powder is magnetic and attracted to the magnet). The thickness of this powder on mag. the roll is determined by a "doctor blade" where the gap between it and the mag. the roller determines the thickness of the toner at mag. roller. Then the powder is transferred from mag. roller to PCR roller (rubber roller) that transfers powder to the OPC roller ie the PCR roller is in contact on one side with the mag. roller and on the other with the OPC roller. The laser beam illuminates the OPC roller and transfers the illuminated portion of the OPC roller or toner to paper. The remaining powder that has not gone to paper wiper or wiper blade is removed from the OPC drum and the powder goes to the waste apron.